Description

The patented innovation of the Dual Media trim design makes it the first and only spring-loaded safety relief valve in the industry that is “dual certified”, as defined by API Standard 520 Part 1 – Sizing and Selection, 10th Edition. Dual Certified is defined as pressure relief valves that are both vapor/gas flow certified and liquid flow certified where dual certification is achieved without making any modifications or adjustments to the relief device when switching fluids during the flow testing. The 1900 DM trim is engineered to perform on both liquid and/or gas media with exceptional blowdown performance and is dual certified to meet dual media (liquid and gas) capacity stamping per ASME B & PVC Code Case 2787. The 1900 DM trim is ideal for any liquid or gas application, two-phase liquid and gas, flashing or multiple relief case scenarios.

Consolidated 11000 Series Safety Relief Valve

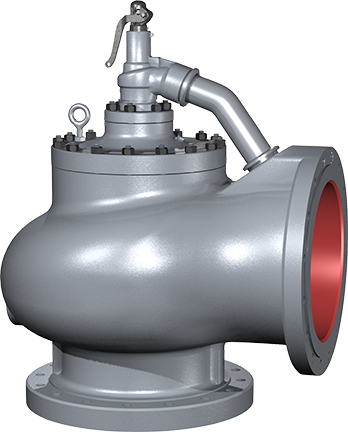

Consolidated 11000 Series Safety Relief Valve Consolidated 3900 MPV Series Pilot Operated Safety Relief Valve

Consolidated 3900 MPV Series Pilot Operated Safety Relief Valve Consolidated 13900 Series Pilot-Operated Safety Relief Valve

Consolidated 13900 Series Pilot-Operated Safety Relief Valve Consolidated 19000 Series Safety Relief Valve

Consolidated 19000 Series Safety Relief Valve 1511 Series Safety Valve

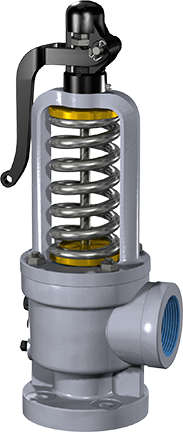

1511 Series Safety Valve Consolidated Maxiflow 1700 Safety Valve

Consolidated Maxiflow 1700 Safety Valve Consolidated 1811 Series Safety Valve

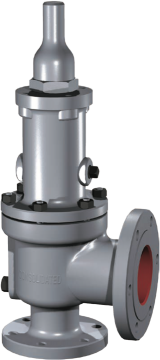

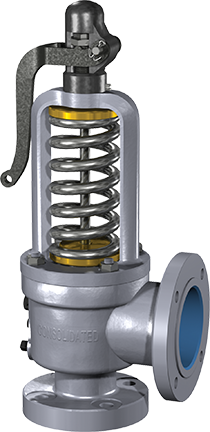

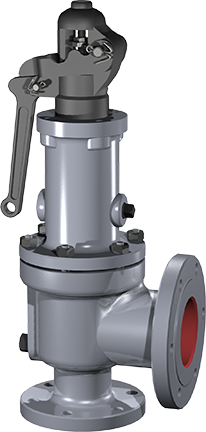

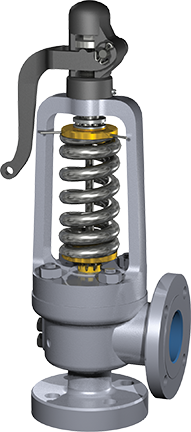

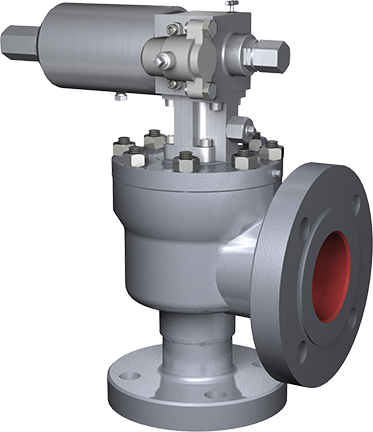

Consolidated 1811 Series Safety Valve Consolidated 1900 Series Safety Relief Valve

Consolidated 1900 Series Safety Relief Valve Consolidated 2700 Series Safety Valve

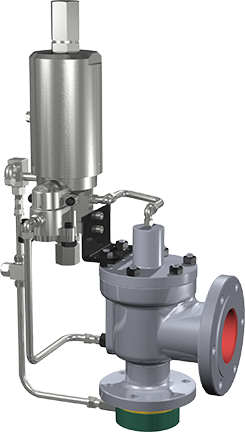

Consolidated 2700 Series Safety Valve Consolidated 2900 MPV series Pilot Operated Safety Relief Valve

Consolidated 2900 MPV series Pilot Operated Safety Relief Valve Consolidated 4900 MPV Modular Pilot-Operated Safety Relief Valve

Consolidated 4900 MPV Modular Pilot-Operated Safety Relief Valve Apollo Valves

Apollo Valves Richter

Richter Consolidated 2900 - 40 series Pilot Operated Safety Relief Valve

Consolidated 2900 - 40 series Pilot Operated Safety Relief Valve Consolidated™️ 1541/1543 Series Safety Valve

Consolidated™️ 1541/1543 Series Safety Valve Consolidated™️ 1982 Series Safety Relief Valve

Consolidated™️ 1982 Series Safety Relief Valve Consolidated™️ 2478 Series Pressure Relief Valve

Consolidated™️ 2478 Series Pressure Relief Valve