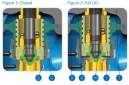

Safety Relief Valves

Consolidated 2700 Series Safety Valve

The Consolidated Type 2700 safety valve is designed to meet the needs of the cobined cycle gas turbine (CCGT) segment.

Industries Served

The Consolidated Type 2700 safety valve is designed to meet the needs of the cobined cycle gas turbine (CCGT) segment.

| SPEC | VALUE |

|---|---|

| INLET SIZES | 1.5" (38mm) through 6" (152mm) in either flanged of weld neck design |

| INLET RATINGS | ASME CLASS 600, 900 and 1500 |

| OUTLET SIZES | 3" (76mm) through 8" (203mm) flanged |

| OUTLET RATINGS | ANSI Class 150 and 300 |

| ORIFICE SIZES | Seven sizes: 1 through Q |

| TEMPERATURE RANGE | -20°F (-28.9°C) to 1050°F (565.6°C) |

| MATERIALS | Alloy and carbon steel cast body with stainless steel trim<br>(standard) special alloys are available for specific applications |

| BLOWDOWN | 4% |

| BACK PRESSURE LIMIT | 25% of set pressure |