Monitek Turbidity Suspended Solids and Color Monitors

Messenger LD & PC Specifications

| SPEC | VALUE |

|---|---|

| Accuracy | +/- 1% F.S. |

| Linearity | +/- 1% F.S. |

| Repeatability | +/- 1% F.S. |

| Sensitivity | +/- 1% F.S. |

| Response time | <1 second |

| Ambient temperature | - 0 ̊C to 45 ̊C (14 ̊F to 113 ̊F) |

| Messenger LD | Stainless steel enclosure: NEMA 4X, IP65 |

| Dimensions | 180 mm H x 160 mm W x 114 mm D (7.1 ̋ x 6.3 ̋ x 4.4 ̋) |

| Weight | 2.77 kg (6.1 lbs.) |

| Messenger PC | Stainless steel enclosure: NEMA 4X, IP65 |

| Dimensions | 375 mm H x 305 mm W x 173 mm D (14.8 ̋ x 12.0 ̋ x 6.8 ̋) |

| Weight | 9.7 kg (21.4 lbs.) |

| Messenger PC | Fiberglass enclosure: NEMA 4X, IP65 |

| Dimensions | 350 mm H x 300 mm W x 173 mm D (13.8 ̋ x 11.8 ̋ x 6.8 ̋) |

| Weight | 5.76 kg (12.7 lbs.) |

| Power and consumption | 100-240 VAC, 50/60 Hz 50 VA |

| Digital Outputs | RS 232, MODBUS; RS 485; USB |

| Analog Outputs | 4 maximum, 4-20mA (self-powered) |

| Relays | 4 (optional) SPST, 250 VAC, 4A, programmable |

| Approvals and certifications | CE – Messenger LD CSA/NEC – General Purpose: Messenger LD, Messenger PC (SS enc.) CSA/NEC – Class 1, Div. 2: Messenger PC (SS enc.) with Z-Purge |

Monispec Color & TSS Sensor Specifications

| SPEC | VALUE |

|---|---|

| Accuracy | +/- 2% F.S. |

| Linearity | +/- 2% F.S. |

| Repeatability | +/- 1% F.S. |

| Calibration Interval | 12 months |

| Response time | <1 second |

| Line Sizes | 10-100 mm (1/2 ̋-4 ̋) |

| Weight | Application & sensor dependent |

| Process Connections | DIN, ANSI, NPT, TH, Tri-Clamp, others |

| Sensor Types | MoniSpec TSS: (formerly MoniSpec A) single wavelength absorbance, total suspend solids, turbidity, & concentration by absorbance MoniTurb Color: (formerly MoniSpec AD) dual-wavelength absorbance color |

| Measuring Range | Application specific (Max. 3 AU) |

| Detector System | 390-850 nm |

| Detectors | Silicon photodiodes, hermetically sealed |

| Sensor Material | 316L SS / 1.4404 (as standard); Hastelloy C, TFMC, others available |

| Windows | Sapphire |

| Sensor Material | Application specific |

| Process Pressure | Max. 15 bar (220 psi) at ambient temperature High-pressure sensors upon request |

| Process Temperature | Max. 140 ̊C (284 ̊F) |

| Optical Pathlength | 1 mm to 500 mm (application specific) |

| Cable Length | Max. 100 m (330 ft) |

| Cleaning Jets | optional |

| Air Purge | optional |

Miniturb (F, S, FS) Turbidity Sensor Specifications

| SPEC | VALUE |

|---|---|

| Accuracy | +/- 2% F.S. |

| Linearity | +/- 2% F.S. |

| Repeatability | +/- 1% F.S. |

| Calibration Interval | 12 months |

| Response time | <1 second |

| Line Sizes | 10-100 mm (1/2 ̋-4 ̋) |

| Weight | Application & sensor dependent |

| Process Connections | DIN, ANSI, NPT, TH, Tri-Clamp, others |

| Sensor Types | MoniTurb F: 12 ̊ forward-scattered light MoniTurb S: 90 ̊ side-scattered light MoniTurb FS: 12 ̊ & 90 ̊ scattered light |

| Detectors | Silicon photodiodes, hermetically sealed |

| Sensor Material | 316L SS / 1.4404 (as standard); Hastelloy C, TFMC, others available |

| Windows | Sapphire |

| Gasket Material | Application-specific, depending on sample temperature or chemical composition. Options include Viton, EPDM, and Kalrez |

| Process Pressure | Max. 15 bar (220 psi) at ambient temperature High-pressure sensors upon request |

| Process Temperature | Max. 140 ̊C (284 ̊F) |

| Optical Pathlength | Application specific |

| Cable Length | Application specific |

| Cleaning Jets | optional |

| Air Purge | optional |

Moniturb & Monispec Sensor Specifications

| SPEC | VALUE |

|---|---|

| Approvals and certifications | Protection: All optical parts protected to NEMA 4X, IP65 ATEX: Zone 1, Zone 2 CSA/NEC: Class 1, Div. 2, Groups ABCD Div. 1, Groups CD General Purpose |

Features and Benefits

Whether you’re brewing beer, optimizing critical pharmaceutical-manufacturing processes, or monitoring industrial wastewater for contamination, you need rugged, reliable, real-time results to optimize your processes and assure consistent quality and regulatory compliance. Galvanic delivers with its Monitek optical-technology-based turbidity, suspended solids, and color monitors, which delivers the highest performance-to-cost ratio of any in-line liquid process monitor on the market today.

The Utmost in Flexibility to Meet Your Toughest Analytical Challenges

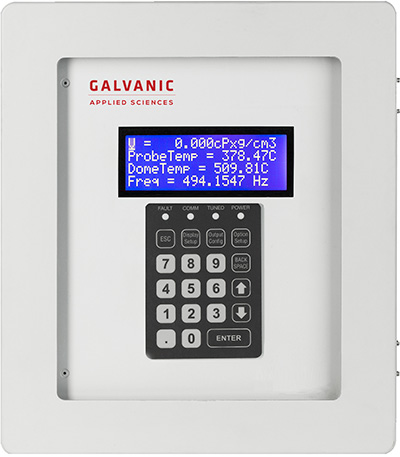

Monitek’s two-component systems include modular, fit-for-purpose in-line sensors and submersible, insertion, and cell-density probes. These sensors pair with a messenger controller, which features intuitive multi-language graphical interface, setup via laptop PC or touchscreen, depending on model, automated cleaning cycles, and more. Unlike most turbidity, concentration, and color monitors, which can handle only one probe at a time, Monitek’s universal messenger controller can handle up to four discrete inputs, each individually controllable to monitor different streams or parameters, dramatically lowering the overall cost and complexity of system set up and operation.

FPA 4100 UV Digital Photometers

FPA 4100 UV Digital Photometers AccuSeries Wet Chemistry Liquid Analyzer

AccuSeries Wet Chemistry Liquid Analyzer Monitek UltraSonic Oil-In-Water Analyzer and TSS Monitor

Monitek UltraSonic Oil-In-Water Analyzer and TSS Monitor ViscoSite In-Line Viscometer

ViscoSite In-Line Viscometer